Wood floor installation

Your hardwood floors are an important investment. Let us help you increase your return on investment with our experience and commitment to service.

Distinctive Wood Floors specializes in the installation of hardwood floors. The skill and know-how of our installers ensures a quality installation with the attention to detail you expect.

preparation is key

Do not fall for the so called flooring “experts” who do a poor site preparation and lack experience. A wood floor installation in your home is quite an investment and really should command more thought than just falling in love with the color of a sample from a display shelf.

The flooring material used in your project is honestly only one part of a bigger equation that factors in moisture, sub-floor preparation, and installation methods. Keep reading and I will detail each component that contributes to an artisanal and successful project.

Milling

make no mistake about it

preparation

A Key first step

Acclimation

prepare the product

project planning

Skilled labor is a factor for project success. However, there are a few extras considerations including preparation of the work area and quality of products to be installed.

01

Sub-floor

Did you know that most squeaks in wood floors are not from the actual flooring, but the sub-floor below deflecting?

Just as a good foundation creates a sturdy home, the area in which you will be installing your flooring requires proper attention. The surface should be properly flattened and squeaks removed. Whether your wood floor installation is factory-finished floor, bamboo flooring, or traditional site finished hardwood floor; it requires a good sub-floor. Please consider that this extra step is often overlooked by some contractors in an effort to keep your costs lower when providing estimates, but could develop into a change order once a project is initiated.

02

Acclimation

Wood is a hygroscopic material which means that it will contract and expand depending on the moisture levels in the air in and out of your home. Actively maintaining a proper balance of moisture around your home will make you a much happier homeowner over the years. Moisture sources can come from a variety of areas, but the air within your home and in the basement or crawlspace has more impact than you may think.

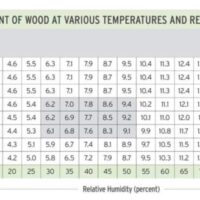

The relative humidity (RH) that is ideal for wood flooring is approximately 30-50% as you can see in the table to the right. Around Bend and central Oregon, the average annual RH in homes with unconditioned HVAC systems is 10-20%. This means that acclimation times can tend to be longer to avoid troublesome gaps later. During our estimate, we will evaluate the moisture conditions of your home in developing an optimal installation schedule. This will ensure long term that your floors are trouble free

03

milling

To make flooring you need to mill it to shape and sometimes construct it using adhesives if it is an engineered floor. The quality with which your floor is milled determines how well it will stay tight and gap-free through time as well as a longer service life. If your wood floor installation does not require an overly aggressive sanding to flatten because of proper milling, then you will have a thicker remaining sanding layer once it is completed. You will be surprised at how spending and extra few hundred dollars up front will give you more value years down the road.

04

fastening method

Flooring materials can be glued, floated, or nailed. Manufacturers of flooring are very specific about details such as fastener length, nailing schedule, adhesive spread rates, and adhesives they allow to be used. We may be required to use cleats instead of staples or adhesive trowels with specific notch profiles. Products that have a factory warranty can lose that warranty from not following manufacturer guidelines. Manufacturer’s guidelines always hold precedence over industry guidelines for wood floor installations.

If you have read everything above, then you can see that we have a lot to talk about during an estimate if you need someone who cares about your investment. We welcome your emails if you are in the planning stage and just need some technical assistance before an on-site estimate. Experience has proven that projects often fail or succeed prior to beginning because of expectations and planning.

OUR company

We are a smaller company by choice. Our hallmarks are:

- Consistency of schedule

- Certified knowledge and experience

- Clean job sites and floor sanding

OUR clients

We love working with clients who appreciate the effort required to deliver a premium floor. We work directly with our clients in order to provide direct communication before, during, and after the project.

OUR technology

We sand and finish all of our wood floor projects using Lagler dust collection sanders. These machines are independently verified by a University to capture dust. We work with only professional grade floor finishes. Depending on your needs, we can provide Swedish finish, low VOC finish, or catalyzed waterborne urethane.

Three Primary product types

avoid confusion and myths:

solid wood flooring

A solid piece of wood from top to bottom of the plank. We generally prefer solid wood flooring for two reasons: service life and predictability of behavior. Solid wood floors tend to have approximately 6-8 sanding cycles available because of the wear layer thickness. This means that your solid wood flooring will likely be around for 100 years or more if it is well maintained. Solid wood flooring also has a more predictable behavior because it is simply one piece of wood within a board as opposed to engineered flooring that has differing expansion and contraction rates because of the multiple materials within one board.

Engineered flooring

Engineered flooring is simply a real wood layer that has been laminated to a plywood core or other materials for extra dimensional stability and to reduce the amount of real wood necessary to make a floor. You can purchase engineered flooring with finish applied at the factory or not.

Factory finished

Factory finished flooring can be EITHER engineered or solid material that was finished at the factory prior to installation on site. Factory finished flooring simply has a time advantage that it can be installed and does not require on-site sanding, but requires extra site preparation for sub-floor flatness and takes a little longer to install. The finishes applied at the factory can be good or not, it really depends on the quality of the product.

Warranty words

As a final note regarding factory-finished flooring, please be careful selecting a product based on warranties, because many warranties exclude scratches, wear and tear and finish issues. In most cases they only cover a structural failure of the floor itself. Understand that quality engineered flooring or factory finished flooring generally is not cheaper than a site-finished wood floor once labor and material costs are combined.